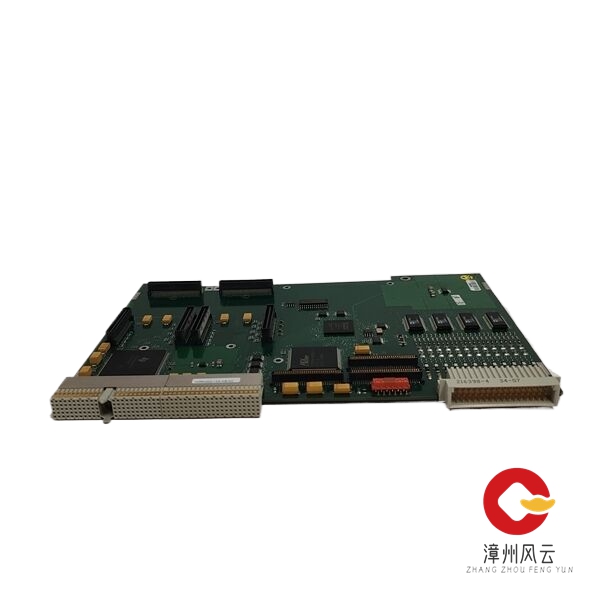

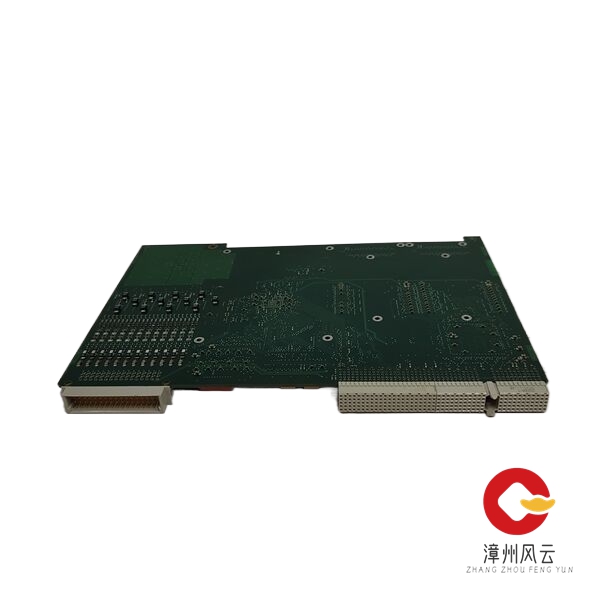

ABB 1MRK002133-ABr02

系统支持多种夹具,进而支持三角形、四边形、梯形等多种抓取模式。夹具上的传感器可以实现工件有无的检测,通过PLC实现对工件掉落、吸附失败等情况的判断及报警,并能够对机械手抓取过程中下降高度的安全保护,通过调节传感器判定距离,实现机械手下降高度超出安全高度时的防护及停机。

ABB 1MRK002133-ABr02

The software uses pattern matching for feature and encoding recognition, and the recognition function includes feature recognition and encoding recognition. Among them, feature recognition is used to identify the feature information of the workpiece, including the type, position coordinates, and R-angle of the workpiece; Encoding recognition is used to identify the spray code information on the workpiece, thereby recording the specific information of the workpiece. In addition, the system will also extract the workpiece's cutting information from the spray code information, thereby sorting the workpiece to the designated tray position and achieving automatic sorting and cutting.

Multiple gripping modes

Flexibly complete part sorting

The system supports multiple fixtures, and thus supports various gripping modes such as triangles, quadrilaterals, and trapezoids. The sensors on the fixture can detect the presence or absence of workpieces, judge and alarm for situations such as workpiece falling and adsorption failure through PLC, and provide safety protection for the descending height of the robotic arm during the grasping process. By adjusting the distance determined by the sensors, it can achieve protection and shutdown when the descending height of the robotic arm exceeds the safe height.

咨询:ABB 1MRK002133-ABr02